What is Konjac Glucomannan

What is Konjac Glucomannan

What is Konjac Glucomannan

What is Konjac Glucomannan

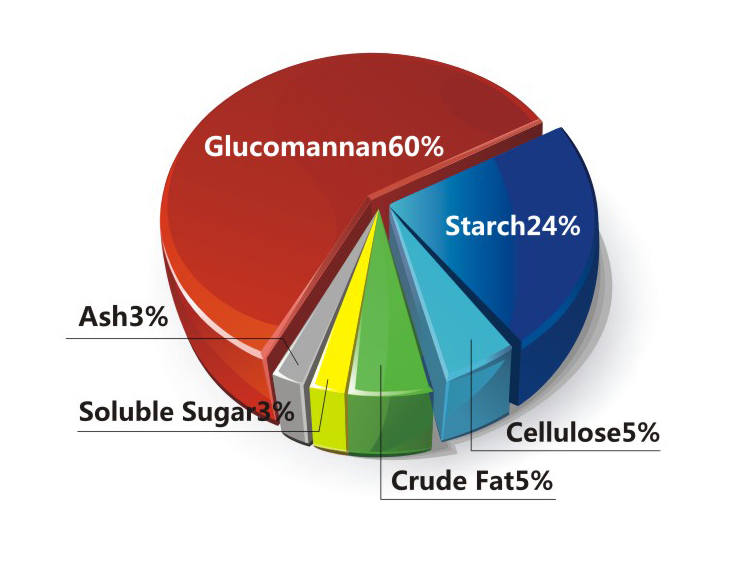

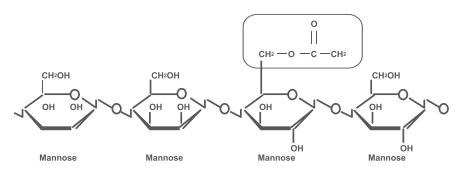

Dry konjac contains 50%-60% glucomannan, 20-30% starch, 2-5% cellulose, 5-10% crude fat, 3-5% soluble sugar (monosaccharide and oligosaccharide) and 3-5% ashy substances (mineral elements). Domestic and international researches show that konjac glucomannan is polysaccharide combined with D-glucose and D-mannose at a gram molecular ratio of 1:1.6 by multiple β-(1-4) glycosidic linkages. Its molecular weight varies from 1,000,000 to 2,000,000 daltons. Konjac Glucomannan is natural dietary fiber with a large molecular weight and extremely high viscosity, Konjac Glucomannan has very high water retaining capacity up to 200 times water to its original volume and turn it into a viscous liquid. Because of its special β-1-4 linked structure of D-glucose and D-mannose, Konjac glucomannan is not affected by human digestive enzymes and contributes no calories. Konjac Glucomannan is widely used as gelling agent, thickener, stabilizer, emulsifier and film former in food, beverage, health care,pet food and chemical industries. |

TYPICAL PROPERTY of KONJAC GLUCOMANNAN

TYPICAL PROPERTY of KONJAC GLUCOMANNAN

1. Great water-binding capability

Konjac glucomannan can be dissolved in cold and hot water, and it is able to bind water as much as 100-200 times. Its water solution is a pseudo-plastic liquid, characterized by shear thinning. One particle of konjac flour consists of extremely long thread-like macromolecules tangled together. When it comes in contact with water, water molecules enter and are absorbed into the chain, gradually causing the particle to swell to about 200 times as its original volume, and turning the konjac flour into viscous liquid.

2. Thickener

Konjac glucomannan’s high thickening property is determined by its highest molecular weight among any dietary fiber known to science, Great water-binding capability and uncharged-particle characteristic. Glucomannan solution with a concentration of 1% can have viscosity as high as 5000-40000mpa.s, which makes it a natural thickener with the highest viscosity than any other natural thickening agents. Konjac flour has the capacity that can make the products keep solid and moisturize structure after being heated, which is not available in any other ordinary thickeners.

3. Stability

Compared with other thickeners like xanthan gum, guar gum or locust bean gum, konjac gum is non-ionic type, thus can hardly be affected by the salt in the system. At ambient temperature, it can still keep stable when the pH value is lower than 3.5. Using konjac gum to replace locust bean gum in dairy products such as ice cream to restrict the growth of ice crystal and stabilize the product quality.

4. Gelling capacity

As a gelling agent, Konjac glucomannan is quite unique for its ability to form thermo-reversible and thermo- irreversible gels under different conditions.

By putting a small amount of alkali into 2%-3% konjac solution, heating to 85℃ in water bath and keeping it still for two hours, an elastic, solid and irreversible gum will be formed. By utilizing its thermo-irreversible characteristic, it may be used to make a variety of foods, such as konjac cake, noodles, bionic food and vegetarian food, etc.

5. Film Former

Konjac glucomannan is a powerful film former - both alone and in combinations with other gums such as K-Carrageenan.

6. Synergistic Effect with Other Hydrophilic Gums

There is an obvious synergistic effect between Konjac glucomannan and K-Carrageenan. Heating and cooling the mixture of the two can formulate a gum with different fragility and elasticity. When both of them are mixed at the ratio of 4:6 or 4.5:5.5, the gum strength reaches the maximum value. Konjac gum also has good synergistic effect with xanthan gum, guar gum, locust bean gum, gellan gum and more.

Nutritional effect of glucomannan

Nutritional effect of glucomannan

Konjac gum is mainly composed of glucomannan, which is a highly soluble dietary fiber with the largest molecular weight and the highest viscosity in nature. It is a highly soluble polysaccharide.